2017-2020

Manufacturing

Cornell Baja

Scroll ↓

The following page is mainly to showcase some of the parts I fabricated on the Baja team. This was a central part of my experience as I would work in the machine shop 6 days a week and would come to Cornell early during winter break to help complete all of our parts. I am very proud of how I was able to make all of these parts, and pass along the skills I learned to other engineers.

Full Spread of Gearbox & Half-Shaft Components from 2019-2020 Season

Electrodes used to plunge EDM spline torque transfer profiles into gears

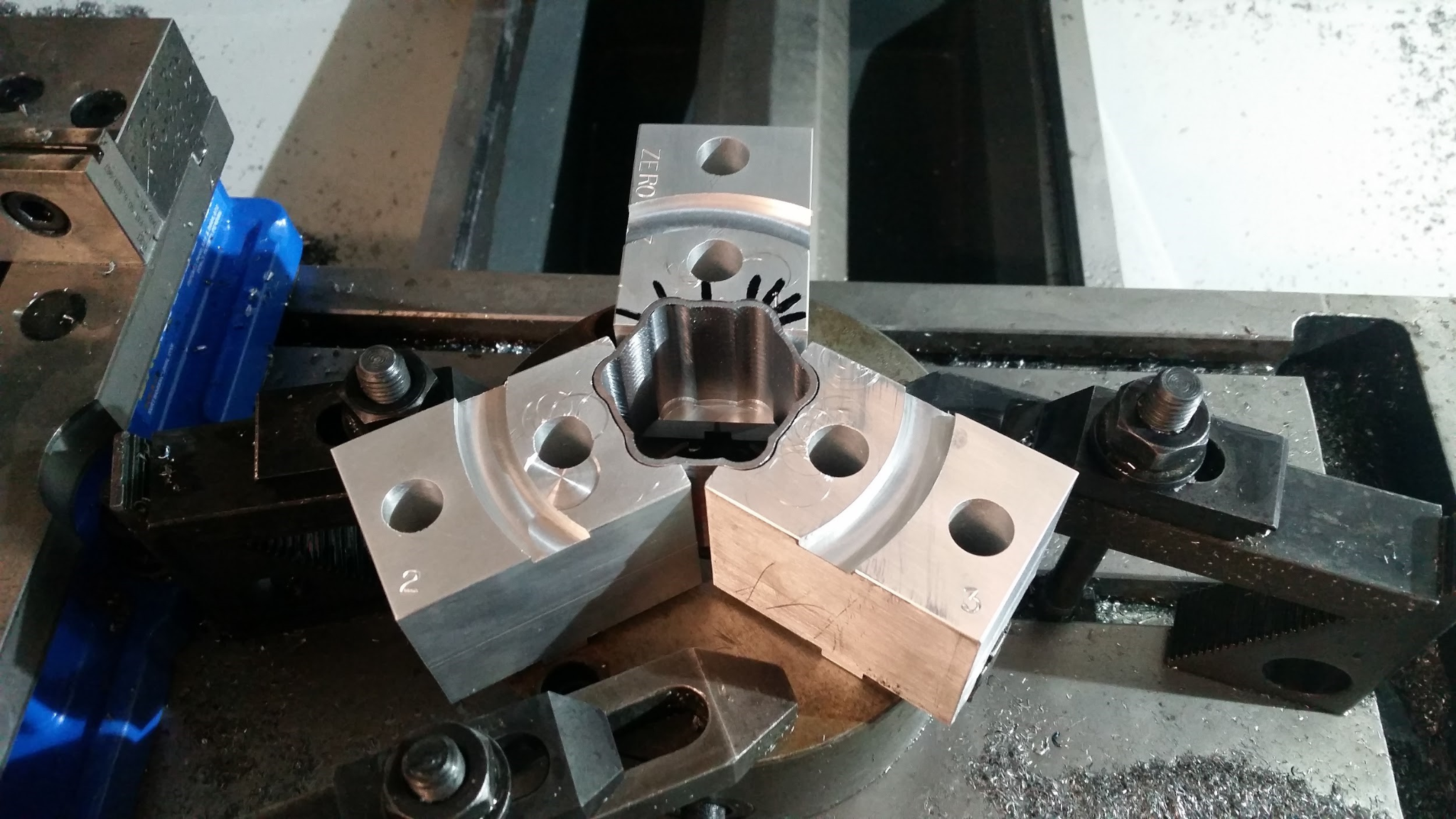

Plunge EDM Process occurring on gearbox shaft

2019-2020 Gearbox casing on fixture in CNC

Steel CV insert tracks machined in custom soft jaw chuck fixture. Even clamping provided reliable work-holding and eliminated risk of crushing inserts. Fixturing also enabled half-thou passes to dial in fit

Large piece of stock loaded up on rotary fixture in CNC

Half-shaft inserts bar fed on CNC Lathe and pre-machined Gearbox Casings with precision bearing surfaces

Gear set blanks and pinion shafts prior to tooth hobbing

Final gear in hobbing machine

2019-2020 Unsprung Corner assembly mock-up with 3D-Printed Upright and sectioned wheel

CVT Primary Pulley, partially machined on CNC

Overrunning clutches machined on CNC Lathe

Normalized 9310 Steel, to reduce residual stresses before machining

2018-2019 Final Gear Set after hobbing and heat treatment

CVT Secondary Pulley on CNC, seated in machining fixture